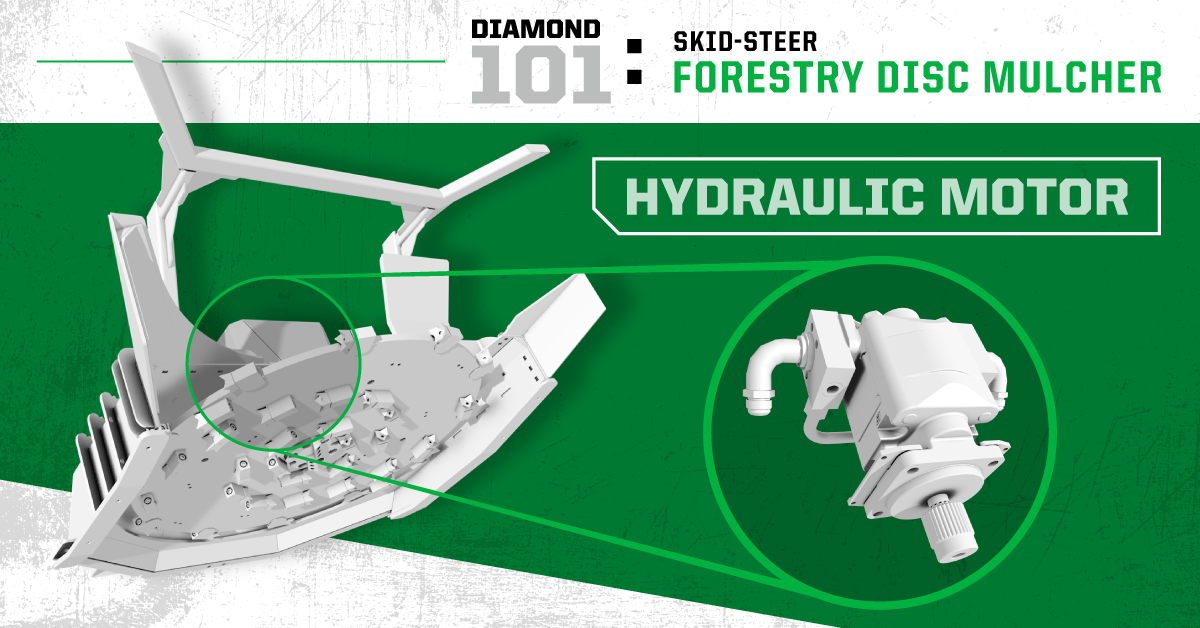

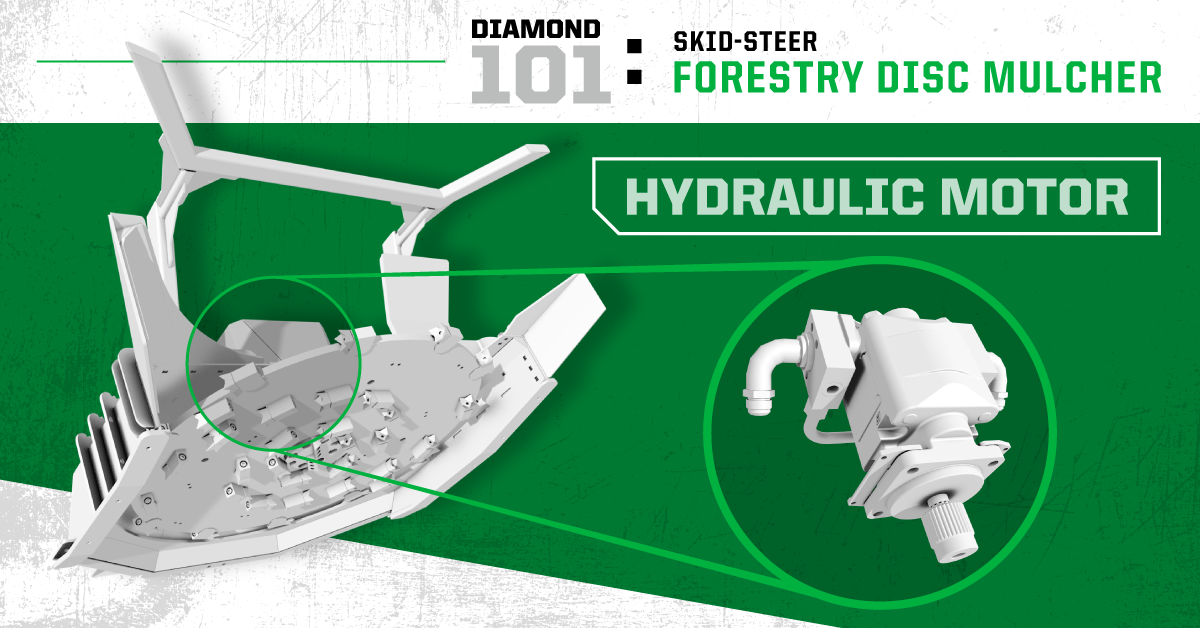

Skid-Steer Forestry Disc Mulcher - Hydraulic Motor Overview

Jun 21, 2019 . 2 min read

There are five fundamental components of Diamond’s Forestry Disc Mulcher; including the motor, teeth, disc, spindle and shell. Why did Diamond choose to use these specific components, and why are they successful? Let’s start with the motor.

HYDRAULIC MOTOR

Diamond‘s Forestry Disc Mulcher is a hydraulically driven attachment. The hydraulic motor turns the hydraulic power into kinetic energy – ultimately powering the teeth through the wood, turning trees into chips.

There are many different types of hydraulic motors on the market with different advantages and disadvantages. When choosing a motor, considerations include the efficiency, contamination tolerance, pressure/flow compatibility and cost.

Diamond currently uses two different hydraulic motors on our disc mulchers, gear

and piston.

Our gear motors are American-made, cast steel gear motors – the highest quality of the type we can source.

Gear motors offer good efficiency, are capable of handling lots of contamination, and are cost effective to purchase and maintain.

These were the motors initially offered on our forestry disc mulcher products, and are still a great option for many applications today. These motors feature a relief valve to protect from over-pressure situations.

PISTON MOTOR OVERVIEW

Our piston motors are a bent-axis, fixed displacement motor sourced from Europe.

These motors are tremendously efficient, and capable of handling very high pressures – well over what modern skid-steers and Compact Track Loader’s (CTL) are producing.

Because of their high efficiency, we are able to use slightly smaller displacements and achieve the same torque relative to our gear motors. This smaller displacement and higher efficiency result in approximately 20% faster disc speeds than the gear motors at the same flow. This 20% increase in disc speed results in over 40% more stored energy in the disc, a tremendous advantage when the going gets tough.

The piston motors offer all the aforementioned advantages while allowing the loader’s hydraulic system to operate cooler. The biggest disadvantage of these motors is their higher price tag.

- High pressure carriers (around 4000 psi) are best paired with the piston motor.

- Commercial contractors, or other high-volume operators, can profit from the productivity gains of a piston motor, and will likely see a return on their investment sooner than a moderate to low user.

- Intermittent users operating mid-pressure carriers (around 3,500 psi or under) should weigh the productivity gains and cooler hydraulic temperatures against the premium price tag. Both options are a good choice, it boils down to preference.

- Casual users, or those price sensitive buyers, should turn to the gear motor - a proven performer for many years.

We love to talk equipment, so even if you’re only a little interested in our disc mulcher give us a call (605) 977-3300, or email: info@DiamondMowers.com

Watch the Diamond Skid-Steer Forestry Disc Mulcher in Action: