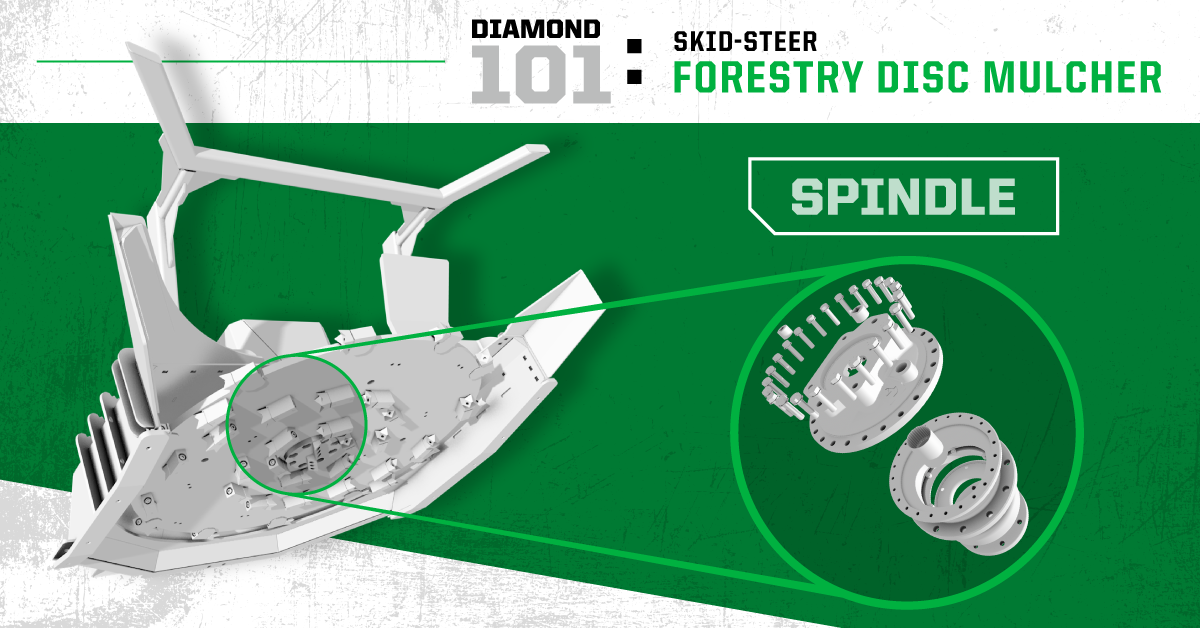

Skid-Steer Forestry Disc Mulcher - Spindle

Aug 08, 2019 . 2 min read

There are five fundamental components of Diamond’s Forestry Disc Mulcher; including the motor, teeth, disc, spindle and shell. Why did Diamond choose to use these specific components, and why are they successful? Let’s look at the spindle.

SPINDLE

The spindle is the central component of the disc mulcher – it’s literally what holds everything together.

This part transfers the torque and power from the hydraulic motor and, at the same time, absorbs all of the stressing coming into the attachment from the disc. From an engineering perspective, this is the most critical part on the mulcher.

DESIGN PHILOSOPHY

There are two divergent thoughts when it comes to disc mulchers or rotary mowers:

1. Use a gearbox to decrease the speed, and increase the torque from the hydraulic motor to

the disc.

-

-

- A gearbox design uses less expensive, smaller displacement hydraulic motors and more commonly available gearbox components.

- The gearbox is made from two shafts, four bearings and is most commonly used “batwing” style mowers.

- With all that complexity in the gearbox, it results in an inherently weaker design and if a failure does occur, it’s very expensive to repair.

- This is a good design for a casual rotary mower user, but is sub-bar for industrial brush cutters and disc mulchers.

-

2. Use a direct-drive spindle assembly

-

-

- This assembly is simple, with a single shaft running through a pair of bearings held in place with a housing.

- The simplicity of the design allows the very large shaft to run through over-sized bearings in a reasonably sized overall package.

- While this is a more expensive arrangement, it is also robust enough to handle the rigors of daily commercial use.

- Diamond has used this option since the company was founded.

-

REPLACEABLE INSERT

Part of an engineer’s job is to think about equipment failure, not just preventing failure but also designing a system where the weakest link is quick and inexpensive to repair. The weakest link in the Diamond spindle is the splined insert.

This insert lives between the output shaft of the hydraulic motor and the direct-drive shaft of the spindle. It is also machined out of slightly softer steel than either of these components, ensuring that the insert will fail first. This insert is relatively inexpensive and can be replaced in approximately 20 minutes in the field with simple hand tools. The alternative is a top-down rebuild of either the spindle or the motor – an expensive and time-consuming repair.

MAINTENANCE

Like the rear axle of a truck, the bearings of the spindle are lubricated with gear oil. This oil needs to be replaced once per year or every 500 hours, whichever comes first. This means that there is no daily maintenance on the entire attachment outside of teeth.

We love to talk equipment, so even if you’re only a little interested in our disc mulcher give us a call (605) 977-3300, or email: info@DiamondMowers.com

Watch the Diamond Skid-Steer Forestry Disc Mulcher in Action: