Skid-Steer Forestry Disc Mulcher - Forestry Teeth

Jul 12, 2019 . 2 min read

There are five fundamental components of Diamond’s Forestry Disc Mulcher; including the motor, teeth, disc, spindle and shell. Why did Diamond choose to use these specific components, and why are they successful? Let’s look at the cutting teeth.

TEETH

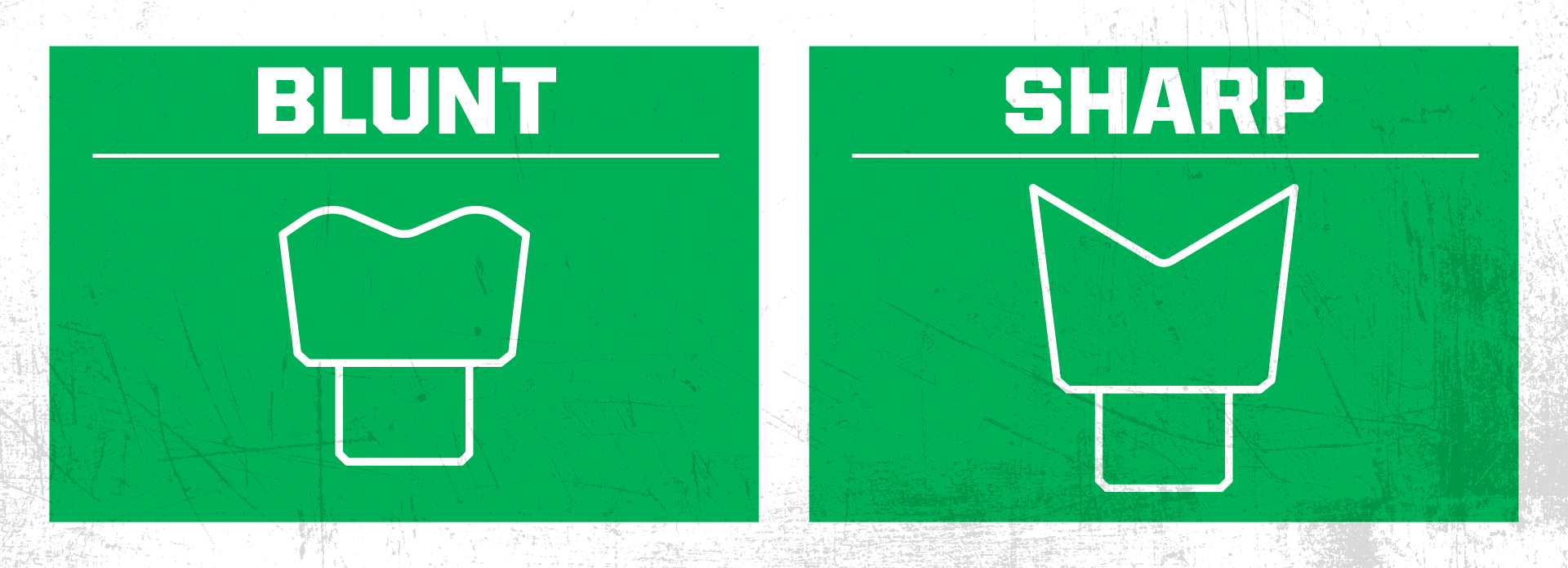

The cutting teeth are also called “tools” in the industry. There are two philosophies when it comes to teeth – blunt or sharp. Both styles have a place in the right application.

BLUNT

Blunt teeth, also called hammers, bludgeon the material apart – they quite literally beat the wood to pieces. This takes a tremendous amount of time and energy / production and fuel, and typically leaved a “shredded” look.

Hammers are typically made of carbide and cost between $75 - $100 to replace. The advantage hammers are there is virtually zero maintenance, and they can withstand contact with the ground. Depending on the type and thickness of carbide, they might also survive impacts with large solid rocks. Hammers are a good choice when the job requires the attachment to mix the mulch into the ground, or constant ground contact.

SHARP

Sharp teeth are typically made of steel and cut or slice the wood apart. They are more productive than hammers, and leave a finer mulch when the job is done. Regardless of the brand, they do require maintenance. Just like a logger stops to sharpen his chainsaw throughout the day, sharp teeth will perform best when they are maintained. Sharpening teeth once per day will yield significantly higher production, cooler hydraulic temperatures, and an overall more enjoyable mulching experience. Diamond’s version of sharp teeth can be sharpened, flipped to offer a fresh edge, and - at the end of their productive life - replaced for less than $25 each. Sharp steel teeth are the right option for high production and intermittent ground contact.

Several companies offer “sharp” carbide teeth. These teeth look just like Diamond’s standard steel teeth, but feature thin layers of carbide on the inside cutting edge. Diamond does not recommend these, as they are far more expensive than steel and the thin carbide shatters on small impacts.

It is extremely important to keep the tooth bolts tight and properly torqued, regardless of style of tooth style or mulcher brand. If the teeth wobble inside the holder, they will wear out the holder and possibly launch from the mulcher at high speed.

TOOTH HOLDERS

Even the best operator will occasionally damage a tooth holder. When this happens, the tooth holder must be replaced immediately or a significant risk of throwing a tooth is high.

Diamond has always built serviceability into the tooth holder design, but the recent evolution to the bolt-on style holder makes replacement in the field even faster and easier. Simply apply a little heat to release the Loctite (a handheld propane torch works well) and replace the holder.

We love to talk equipment, so even if you’re only a little interested in our disc mulcher give us a call (605) 977-3300, or email: info@DiamondMowers.com

Watch the Diamond Skid-Steer Forestry Disc Mulcher in Action: